CNC Precision Machining Explained: The Backbone of Reliable Manufacturing

Welcome to Genesis-MFG, a reliable source for custom manufacturing. We offer precision-engineered solutions, taking into full consideration any unique production demands. Our accomplished team, equipped with the latest technologies, gives optimum aid and support in designing, developing, and manufacturing quality products to your satisfaction.

Manufacturing has always relied on precision.

But in todays world, where performance, safety, and speed are non-negotiable, CNC precision machining has moved from being a technical advantage to an absolute necessity.

From aerospace components to oilfield tools, UAE industries are investing in accuracy like never before.

And behind that accuracy is a silent hero: Computer Numerical Control, or CNC.

This article will walk you through exactly what CNC precision machining is, how it works, and why its considered the core of reliable modern manufacturing across the UAE.

Lets get into it.

Why Accuracy Matters More Than Ever

In industries like oil & gas, defense, and automotive, there is zero room for guesswork.

When one part doesnt fit, the entire system can fail, sometimes catastrophically.

That's why every cut, edge, and hole in a component has to meet exact specifications.

This is where CNC precision machining changes the game.

Instead of depending on human skill alone, this technology ensures machines follow exact instructions down to fractions of a millimeter. That kind of accuracy guarantees reliability, and thats what makes it invaluable to modern industry.

In short: reliable parts equal reliable operations.

A Simple Breakdown of CNC Precision Machining

So, how does it all work?

At its core, CNC precision machining uses computer software to control complex tools, like drills, mills, and lathes, that cut and shape materials with extremely tight tolerances.

Instead of relying on manual control, the machine is programmed to do the same exact job again and again, without deviation.

Think of it like printing a document, but instead of ink on paper, youre shaping solid materials into perfect forms.

This makes CNC the top choice when your parts need to be identical across thousands of units, or just one flawless prototype.

Why UAE Industries Are All In

The UAE is building a future on innovation, speed, and self-reliance.

To compete globally, local manufacturers must produce parts that meet international standards, and do it fast.

Thats why more and more companies are partnering with CNC machining companies in the UAE like Genesis MFG.

This shift is being seen across Dubai, Sharjah, Abu Dhabi, and beyond.

Local production removes delays, lowers shipping costs, and allows for more control.

Genesis MFG is particularly known for combining technology with hands-on expertise, making them a go-to partner for high-performance industries.

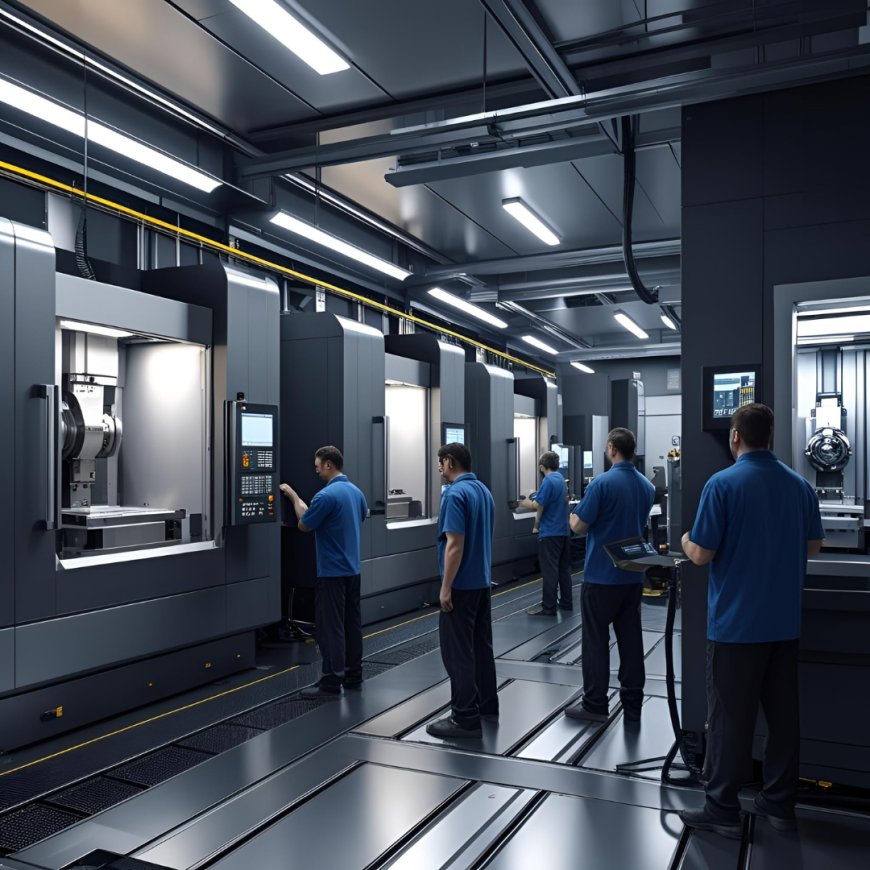

Inside Genesis MFG: UAEs CNC Powerhouse

If youre wondering where all this precision is coming from, look no further than Genesis MFG.

Theyre not just machining experts, theyre engineers who understand both the process and the purpose.

Working with clients in defense, energy, aerospace, and industrial manufacturing, Genesis MFG delivers components that meet exact specifications, tight deadlines, and the most demanding quality checks.

Theyve also earned their place among the top CNC machine suppliers in UAE, helping other companies bring machining capabilities in-house.

Genesis doesnt just supply machines. They run them daily, test them rigorously, and train teams to use them effectively.

That dual capability, machining and supplying, puts them in a league of their own.

What Is Precision Manufacturing Really?

Youve probably heard the term, but lets clear it up.

What is precision manufacturing?

In the simplest terms, its the practice of creating parts that match exact specifications, without error.

Whether its the diameter of a hole or the angle of a curve, every element must be exactly what the design demands.

This isnt just about getting the part to work. Its about making sure it performs over time, under stress, and in real-world conditions.

Thats why precision manufacturing is so essential to industries where durability and function matter more than anything else.

And CNC is the technology that makes it all possible.

The Shift from Manual to Machine

Before CNC, machinists relied on tools, skill, and muscle memory to shape parts.

But no matter how good a human is, theyre not a machine.

Manual work takes longer, costs more, and can never match the consistency of CNC.

Now, with CNC precision machining, companies can program a machine once, and let it run for hours or days, creating thousands of perfect parts.

Not only does this save time, but it also dramatically improves accuracy and reduces waste.

Its this combination of speed, consistency, and quality thats fueling the CNC boom across the Emirates.

Why Genesis MFG Is More Than a Machining Vendor

Its one thing to offer CNC services.

Its another to understand your clients industry, goals, and deadlines.

Thats where Genesis MFG stands out.

They dont just produce parts, they solve manufacturing challenges.

They work with engineers and procurement teams to ensure designs are manufacturable, costs are controlled, and results are exactly what the client needs.

This is why Genesis is trusted not just for their machining, but for their brains, insight, and real-world support.

Theyre helping push the limits of what CNC machining companies in the UAE can offer.

What CNC Precision Means for UAEs Industrial Future

As the UAE moves toward more localized, self-reliant industrial strategies, CNC precision machining will only grow in importance.

Manufacturing isnt just about having machines.

Its about having the right machines, the right people, and the right systems in place to meet international standards and aggressive deadlines.

Genesis MFG is helping build that future by offering CNC solutions that are reliable, scalable, and industry-ready.

From rapid prototyping to large-volume production, theyre helping UAE industries manufacture smarter, not harder.

Conclusion

CNC precision machining isnt a luxury anymore, its a core requirement for any business that values quality and consistency.

As UAE industries scale, export, and innovate, having the right CNC partner will separate the leaders from the rest.

If your business depends on quality components, reliable timelines, and repeatable results, the message is clear:

Precision isnt optional. Its essential.

And CNC machining, with companies like Genesis MFG leading the charge, is the backbone that keeps it all running.

FAQs

Q1: What makes CNC machining more reliable than traditional methods?

Because it eliminates human error and guarantees accuracy through computer control and automation.

Q2: Can small businesses in the UAE benefit from CNC machining?

Absolutely. CNC is scalable, from one-off prototypes to high-volume manufacturing.

Q3: Why is Genesis MFG trusted across industries?

Because they combine CNC expertise with deep industry knowledge, hands-on support, and unmatched quality control.

Q4: How is CNC machining connected to precision manufacturing?

CNC machining enables the ultra-precise production required for industries where failure is not an option.

Q5: Does Genesis MFG also supply CNC machines?

Yes. They are one of the top CNC machine suppliers in UAE, offering setup, training, and long-term support.